Smart clothing will soon be a part of everyday life in the workplace. Medanta, the manufacturer of antimicrobial workwear, and Suunto, the creator of Movesense sensor technology, are working together to develop smart clothing that increases safety, well-being and enjoyment at work. Smart textiles can make the work of busy chefs and healthcare professionals easier and improve patient safety.

Steaming pans, hot ovens and precise timing. Restaurant kitchens are often hectic, and the ambient temperature can get high. A busy chef may not be able to anticipate when it's time to take a break.

"In many professions, thermal conditions are a challenge for both occupational safety and enjoyment at work. In such cases, it would be good to be able to monitor an employee's thermal load in real time during the working day. By measuring the employee and the conditions, for example, a restaurant company can support the health and well-being of its employees," says Kimmo Pernu, Innovation Architect at Suunto.

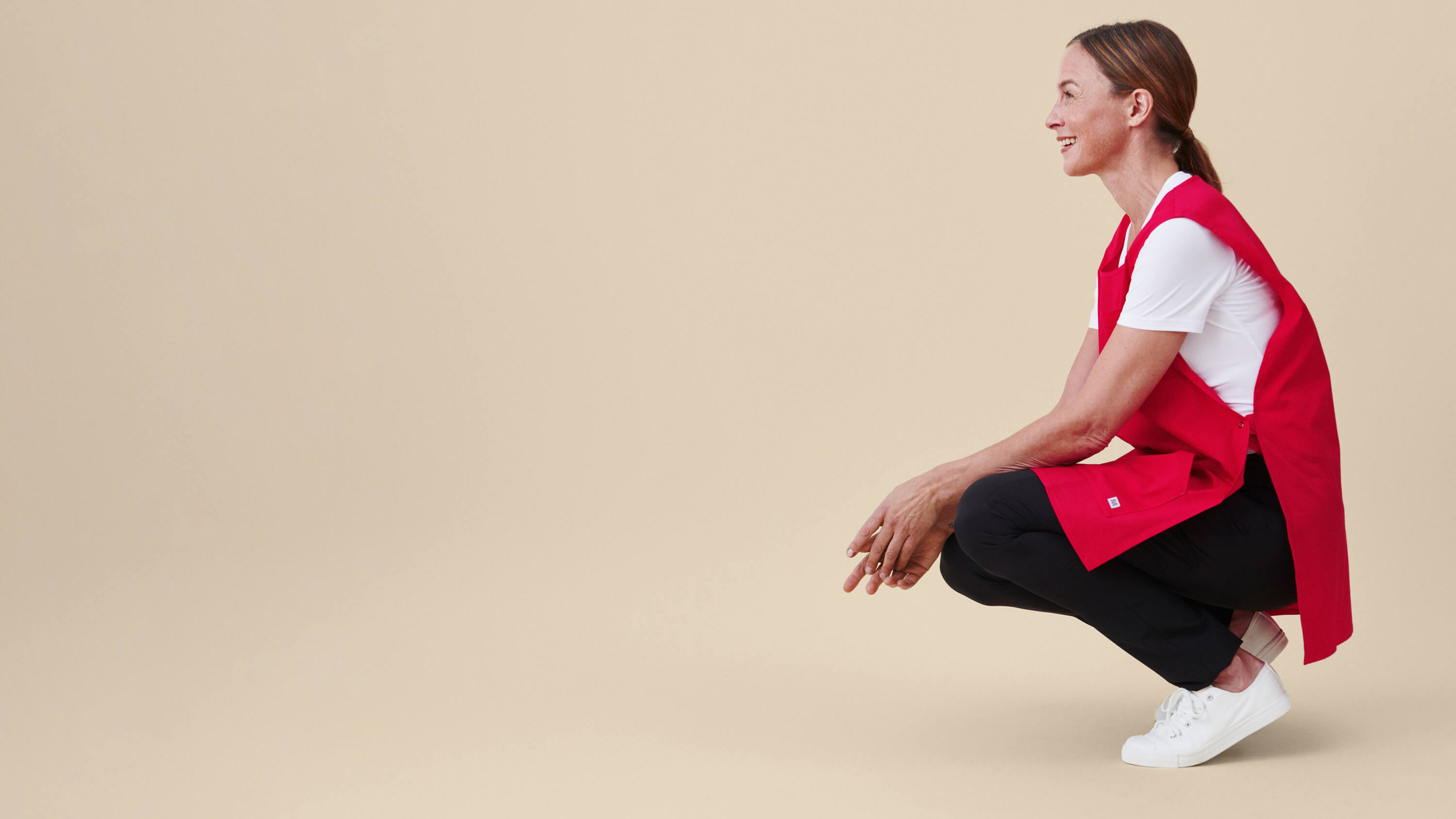

Work stress can be monitored with Suunto's Movesense sensors, which measure, among other things, a person's body temperature, movement and heart rate, as well as the temperature of the work environment. Smart clothing has not yet been seen in restaurant kitchens, but soon smart chef coats equipped with sensors could be a natural part of employees' everyday lives.

In spring 2020, Medanta, a manufacturer of antimicrobial workwear, and Suunto will test a smart jacket they developed together in the kitchens of two Helsinki restaurants.

Smart clothing meets customers' everyday challenges

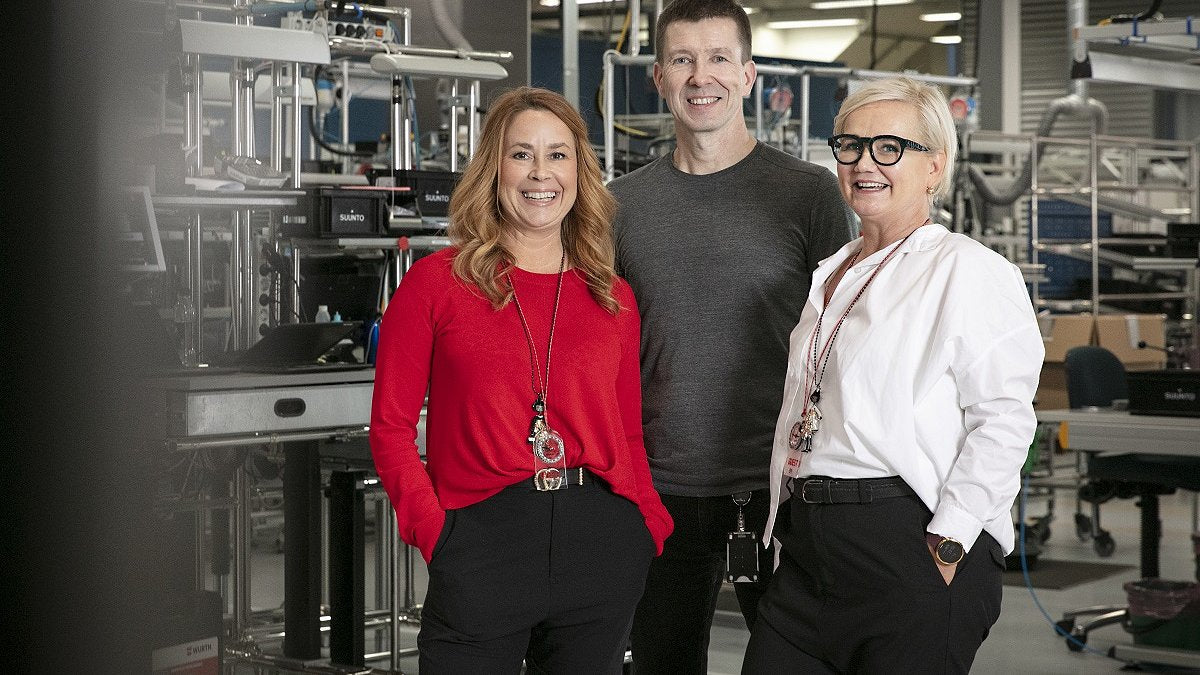

Medanta's CEO Anu Kivelä says that the collaboration with Suunto originated from the needs of Medanta's customers.

“We set out to develop wearable technology because we want to serve our customers as well as possible. This requires us to understand their business in greater depth and detail. Our customers' wishes and the everyday challenges they face were the main reasons why we contacted Suunto in spring 2019.”

According to Kimmo Pernu, the collaboration with Medanta has also been an interesting step for Suunto: workwear is a high-potential area where Movesense technology can be utilized in many ways.

According to Pernu, the small and lightweight motion and biometric sensor is easy to attach discreetly to work clothes.

“The chefs don’t have to change their routines. They put on their normal work clothes – and they now happen to have our measurement technology. The contact temperature sensor is sewn into the jacket, and the removable radio device that handles data transfer and all the calculations is attached to it with a snap.”

The best place for the sensor was chosen to be the shoulder area, where the sensor has good contact with the skin due to the weight of the fabric.

"The sensor could not be placed on the front of the garment: the front is an active area where manual work is done, and the sensor must not get caught on anything or accidentally fall into a pot. The information transmitted by Movesense is directed to the cloud, and the technology can be used to utilize the possibilities offered by artificial intelligence, for example," says Pernu.

Intelligence increases well-being and productivity

The sensors in Medanta's chef's jackets first send the data they measure via Bluetooth to a base station in the kitchen, from where the data continues to an analysis service in the cloud.

The restaurant can analyze and utilize the results in any way it wants – of course, by agreeing on the rules of the game with its employees.

Anu Kivelä and Kimmo Pernu are eagerly awaiting the results of the pilot. The Occupational Safety and Health Act already stipulates the conditions and standards that must be met if additional rest breaks are exceeded.

"For example, the application could assess the need for a recovery break and prompt it. Measurement-based information increases employee safety, supports health, and increases productivity by reducing sick leave. The most obvious benefit of smart clothing is that a company can better take care of its most valuable capital, i.e. motivated employees," says Pernu.

Technology withstands industrial washing

Kimmo Pernu has extensive experience in sensor technology, having been developing wearable measurement technologies at Suunto and Amer Sports for 15 years. Suunto is part of the Finnish Amer Sports group, which owns several globally renowned sports brands, such as Salomon, Atomic and Wilson.

Initially, Suunto developed sensor technology for its own needs: Movesense has enabled the creation of special applications and services for different sports.

“Other companies started to become more and more interested in our technology, so we decided to create a new business model, our own internal start-up. The goal was to build a ready-made sensor around which our customers could easily create their own applications.”

Anu Kivelä praises that the partnership with Suunto has gone well. The division of labor is clear: Suunto is responsible for the measurement technology, while Medanta takes care of attaching the sensors and integrating them into the clothing.

"A big challenge for us is how the sensors will survive the industrial washing process. We will also test this during the piloting. Good workwear is not only durable, but also as simple and carefree to use as possible. We don't want the sensors to have to be removed for washing," says Kivelä.

Smart clothing increases patient safety

Medanta and Suunto's collaboration starts with chef coats, but there is an equally great need for smart clothing in healthcare. In the future, it will be increasingly difficult to recruit staff for the sector as the large age groups age and the birth rate decreases.

“All solutions that can reduce routine human work directly correlate to cost savings,” says Anu Kivelä.

A sensor attached to a patient's clothing allows, for example, the progress of a patient's treatment to be monitored in real time.

“While a nurse currently visits a patient several times a day to take their temperature or ECG, Movesense technology continuously measures the readings – freeing up staff time for activities other than routine procedures. The information can help in better planning care.”

Kimmo Pernu also sees great opportunities in health technology.

“We participated in the international Medica trade fair in Germany last November. It is the world's largest trade fair for the medical and healthcare industry, and in discussions with industry experts, it became clear that there is not much similar open interface motion and biometric measurement technology available – meaning we are firmly among the pioneers.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.