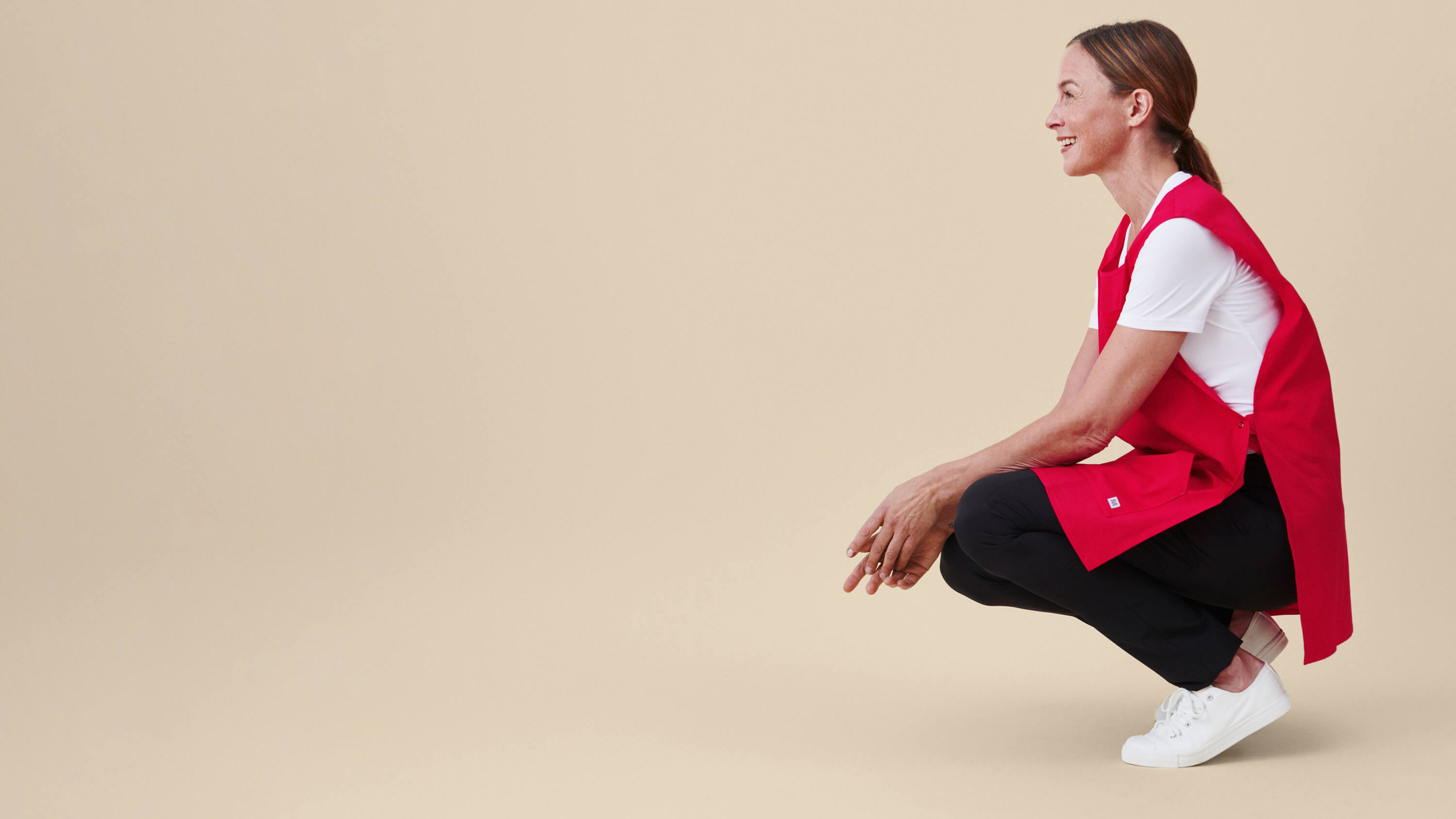

The Finnish smart jacket combines Suunto technology and Medanta's antimicrobial material. Chef Mikko Kaukonen put the smart jacket to the ultimate test in preparation for the prestigious Bocuse d'Or chef competition.

Chef Mikko Kaukonen tested the smart clothing while preparing for the Bocuse d´Or competition at the Stadin Vocational and Adult Education Institute in Roihuvuori, Helsinki. Kaukonen practiced preparing the competition menu for five and a half hours – the same amount of time he will have at his disposal for the actual competition in June 2021 in Lyon. Kaukonen and his team won their ticket to Lyon in mid-October in Tallinn, placing fifth in the Bocuse d´Or European qualifiers .

Smart clothing sensor measures movement and temperature

Sensors in smart clothing collect information that can be used to plan measures to increase well-being and safety at work. The sensor attached to Kaukonen's chef's coat measured, among other things, body temperature, movement, and the temperature of the work environment.

"Everything that promotes well-being at work is important. The most important thing is that the information provided by the sensors is actually utilized in practice, so that the hectic and hot working conditions in restaurant kitchens can be improved," says Mikko Kaukonen.

Smart cooking has also been developed in collaboration between Finnish companies Medanta and Suunto . The Fredman Group, which develops kitchen technology and is involved in the collaboration, focuses on data storage. With their innovation, they aim for both domestic and international markets.

Measurement increases occupational safety and health

"In the near future, smart clothing will be a part of everyday life in workplaces where the working environment and conditions are particularly demanding and stressful. For example, in the food industry and professional kitchens, work requires a lot of repetition and working conditions can be particularly hot or cold. Developing smart clothing requires expertise in many different fields, and when we combine our skills and strengths, it is possible to achieve top results," says Anu Kivelä, CEO of Medanta.

Measurement-based information increases employee safety, supports health, and increases productivity by reducing sick leave.

“The most obvious benefit of smart clothing is that a company can better take care of its most valuable asset, its motivated employees. Small and lightweight motion and biometric sensors can be easily attached to work clothes inconspicuously. For example, chefs do not need to change their routines, but simply wear their work clothes as normal,” says Kimmo Pernu, Innovation Architect at Suunto.

Leave a comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.